Concrete

Concrete is an example of a large particulate reinforced composite material. It is

an important structural material that, by tonnage, is used more than

steel in the U.S.

Concrete is basically a ceramic aggregate composite material

that is composed of fine and coarse aggregates (60–80%) embedded in a

hard matrix of a cement paste and water, sometimes with entrained

air. The

compositions can vary considerably.

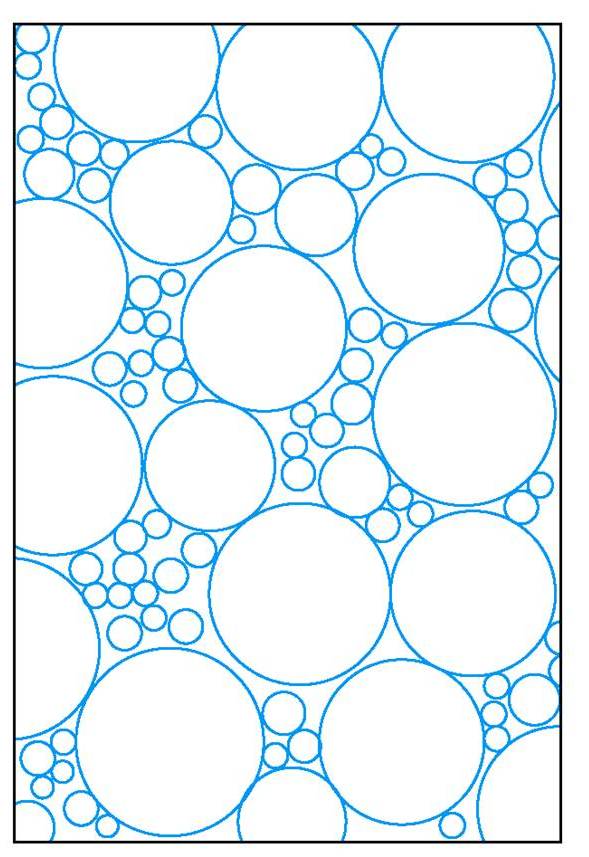

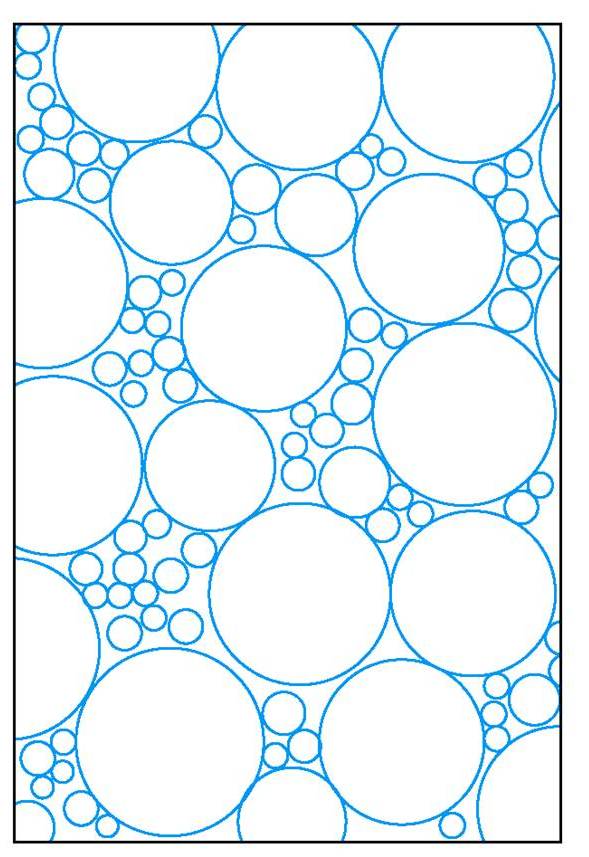

In this two-dimensional

schematic we see that filing the volume of concrete with aggregate is

aided by a wide particle-size distribution. The smaller particles fill

spaces between larger ones. A dense packing with good interfacial contact is desired, so

it needs to be mixed well in order that all particulate surfaces are

covered. Water is needed for the bonding reactions of the cement,

however, too much water will weaken the final product.

Advantages of concrete:

- high compressive strength (~10-15 times greater than its tensile strength)

- economic

- durable

- fire resistant

- ability to be fabricated and cast on site

- aesthetic appearance

Disadvantages of concrete:

- low tensile strength (TS can be 10-15x lower than CS)

- low ductility

- some shrinkage

- thermal stresses occur with temperature changes

Portland Cement Concrete

The most common concrete is made with Portland cement.

- Portland

cement is very commonly used in the concrete industry and has a wide

variety of compositions that include various forms and percentages of

different calcium aluminosilicates.

- Hardening of Portland cement is accomplished by reactions with water, which are

called hydration reactions. These reactions are complex and not

completely understood. The extents to which the hydration

reactions are completed determine the strength and durability of the

concrete. It is important that the concrete retains water during

the early curing period and that evaporation (drying) is prevented.

- Portland cement is a hydraulic cement because water is involved

in the reactions. A nonhydraulic cement employs other compounds in the

hardening reactions. For example lime employs CO2.

- Water that is left over and trapped in the cement will tend to

weaken the concrete. A water-to-cement ratio above 0.4 decreases

the compressive strength of concrete significantly. However there is a

limit to how low the water-to-cement ratio can be since less water

makes it more difficult to work the concrete and have it completely

fill the forms.

- Entrained air will provide

workability to cement allowing the water content to be less.

Entrained air will also increase the cement’s resistance to freezing

and thawing.

- The properties of concrete will

depend on the proportioning of its ingredients: cement, fine

aggregates, coarse aggregates, water and air. The American Concrete

Institute sets the methods of proportioning concrete mixtures.

- The design of concrete mixtures should include consideration of the following factors:

- Workability

- Strength and durability

- Economy of production

Chemical Composition of Portland Cement

- Tricalcium silicate: 3CaO SiO2 (abbreviated: C3S)

- Dicalcium silicate: 2CaO SiO2 (abbreviated: C2S)

- Tricalcium aluminate: 3CaO Al 2O3 (abbreviated: C3A)

- Tetracalcium aluminoferrite: 4CaO Al 2O3 Fe2O3 (abbreviated: C4AF)

Different amounts of these compounds give different types of Portland Cement

- Type I – general purpose such as sidewalks, buildings, bridges, culverts and tanks, and reservoirs.

- Type II – used where moderate sulfate attack is expected such as

in drainage structures or in hot weather since this type has a moderate

hear of hydration.

- Type III – early-strength type; develops high strength in an early period.

- Type IV – a low-heat-of-hydration portland cement used when the rate and amount of heat must be minimized.

- Type V – sulfate-resisting cement used when the concrete is exposed to severe sulfate attack.

- Type xxA – the A means that air entraining agents have been added.

Manufacturing Portland Cement

The process to make portland cement:

- calcinations - grind and mix clay and lime bearing minerals

- heat to obtain a material called clinker

- grind this to a powder

- add gypsum (CaSO4 2H2O) to retard setting process

Improving the TS of Concrete

Since the TS of concrete is about 10 – 15 times lower than its

CS, it is mainly used in compression. However, there are ways to

enable it to sustain tensile forces:

- Reinforced concrete

The concrete is cast with steel reinforcing

bars, wires, or mesh so that the tension forces are transferred from

the concrete to the steel reinforcement through bonding. Other

reinforcing materials include fibers of glass, steel, nylon, or

polyethylene. Caution must be taken as the cement can deteriorate

some materials. - Prestressed concrete

Can be pretensioned or posttensioned. The idea is to introduce

compressive stresses into it so that they have to be counteracted

before the concrete is subjected to tensile stresses.