Interfacial Strength

The

interfacial strength refers to the strength of the bond between the

matrix phase and the dispersed phase. Usually interfacial strength is

desired.

Interfacial Strength in PMCs and MMCs

In polymeric matrix and metal matrix composites high

interfacial bonding is desirable so that the stress can be transmitted

from the matrix phase to the dispersed phase in order to maximize the

overall composite strength. (The dispersed phase is usually the stronger material.) If

the bond between the matrix phase and the dispersed phase is not strong

enough to transmit the stress, then the reinforcing phase slips out of

the matrix and the strength of the fibers will not be transmitted

to the matrix.

Interfacial Strength in CMCs

A

case where interfacial strength is not desirable is the

case of ceramic matrix composites. In these composites failure

originates in the matrix. In order to maximize the fracture toughness

for these, it is desirable to have a relatively weak interfacial bond

allowing the fibers to pull out. As a result, a crack initiated

in the matrix can be deflected along the fiber-matrix interface.

This improves fracture toughness.

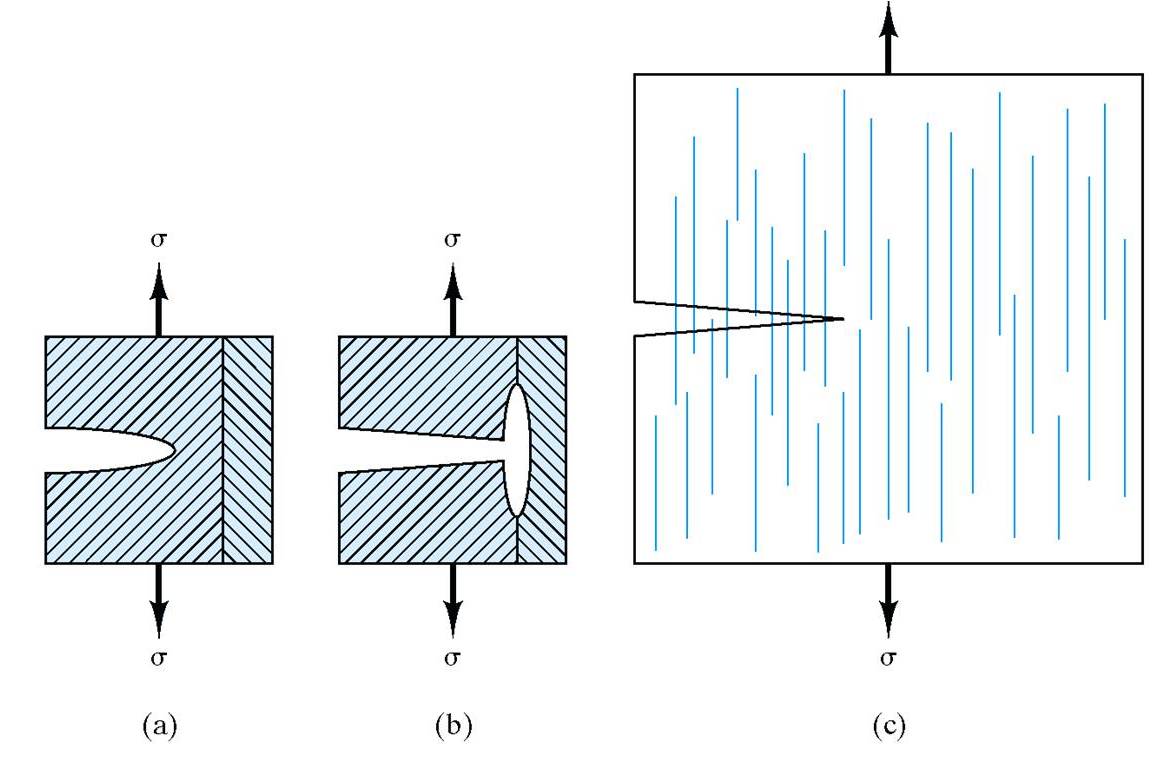

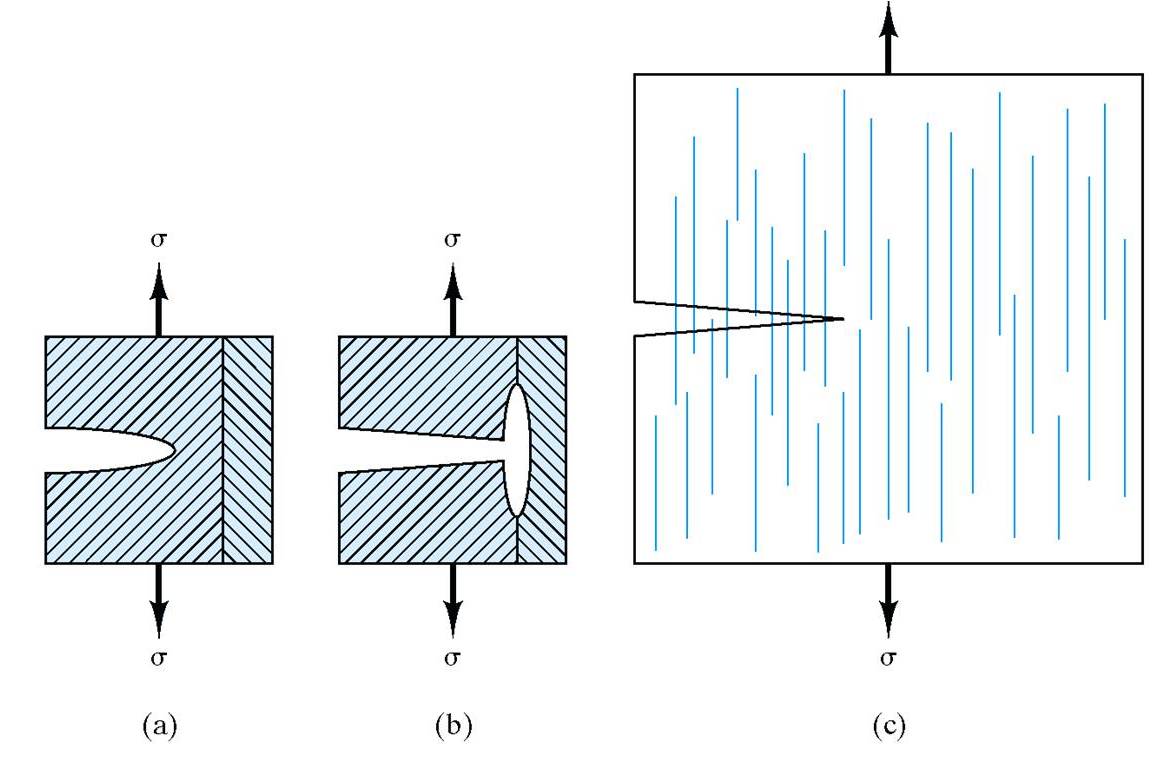

In

this picture we we see a matrix crack approaching a fiber in figure

(a).

It is deflected along the fiber-matrix interface as shown in

figure (b).

For the overall composite shown in figure (c), the

increased crack path length due to fiber pullout significantly improves

fracture toughness.

Factors to consider for interfacial bonding:

- surface treatment

- chemistry

- temperature