Property Averaging for the Case of Isostrain

The

properties of a composite must, in some way, represent an average of

the properties of their individual components. The precise

nature of the "average" is a sensitive function of the microstructural

geometry.

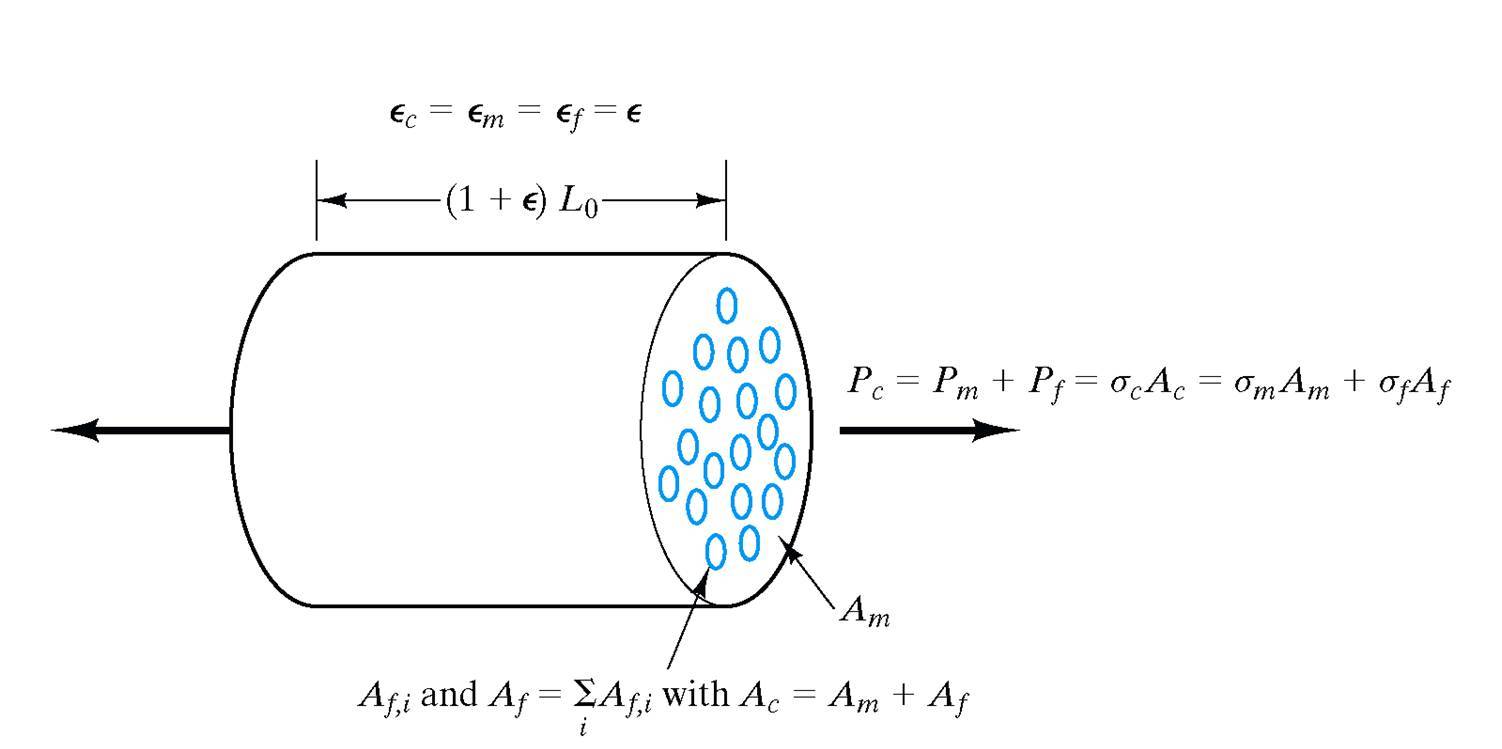

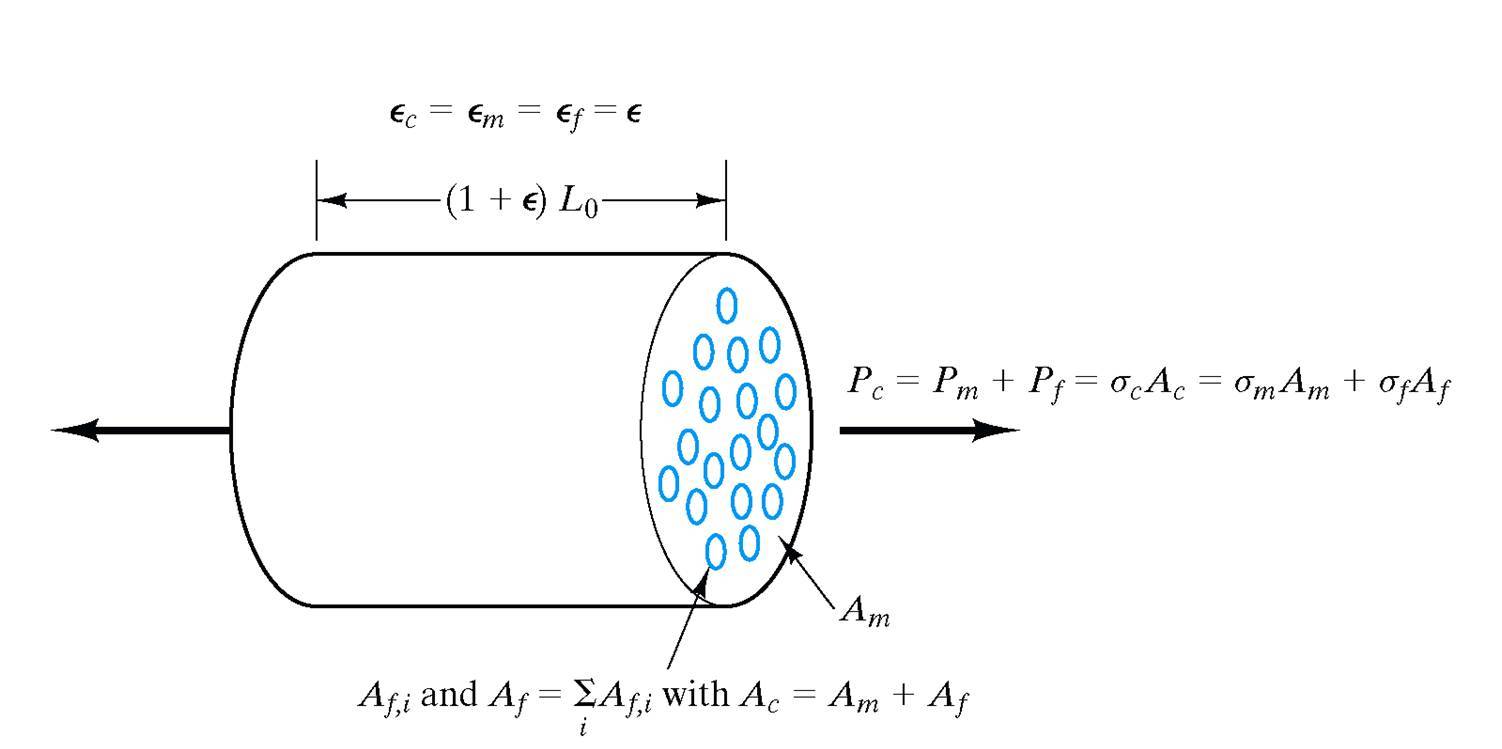

Calculating Young's Modulus for a Composite Material Under Isostrain

We

will look at a specific case of calculating the modulus of elasticity

for a composite material with continuous aligned

fibers parallel to the loading. This specific case is called isostrain since the strain of the fibers and the matrix is the same:

ec = em = ef = e

This of course assumes that the

matrix is intimately bonded with the fibers.

The load that the composite carries is the sum of the load on the fibers and the load on the matrix:

Pc = Pm + Pf

Substitute an expression for the load, P, using the stress (P = sA):

scAc = smAm + sfAf

Now substitute an expression for the stress, s, using the strain and Young's modulus (s = eE):

ecEcAc = emEmAm + efEfAf

And since ec = em = ef = e we have:

eEcAc = eEmAm + eEfAf

Cancelling out the e and solving for Ec gives:

Ec = (Am/Ac) Em + (Af /Ac)Ef

If Vm & Vf are volume fractions of matrix and fibers respectively, we finally have our answer:

Ec = VmEm + VfEf

So

we see that for this case of isostrain conditions, the composite

modulus, Ec, is simply the weighted average of the moduli of the

components.

Calculating Other Properties for a Composite Material Under Isostrain

Although the above derivation was for Young's modulus, the relationship we obtained holds for many material properties.

In general for isostrain conditions:

Xc = VmXm + VfXf

where X is:

- E, Young’s modulus

- D, diffusivity

- k, thermal conductivity

- sigma, electrical conductivity

- nu, poisson’s ratio

Calculating Fraction of Load Carried by Fibers Under Isostrain

Let’s also examine the total fraction of the load carried by the fibers:

Pf /Pc = sfAf/scAc

Pf /Pc = eEfAf / eEcAc

Pf /Pc = (Af/ Ac )(Ef/ Ec)

Pf /Pc = Vf (Ef / Ec)

Since Ef >> Ec this can be very effective. It means that the high strength fibers will carry most of the load. For

some fiberglass, the fibers can carry ~96% of the load! The ductile

matrix make this a less brittle material. Hence we get the “best

of both worlds”: strength and ductility!