Composite Materials

Composites

are materials that are mixtures of two or more components which are

essentially insoluble in each other. The components are taken from the

fundamental structural material types: metals, ceramics, glasses,

polymers. The result is a material that has superior properties to

any of the constituents alone: "The best of both worlds."

Many composites have

just two components: A matrix phase with some kind of dispersed phase. The

classic example of a composite material is fiberglass which consists of

micron-scale reinforcing glass fibers in a polymeric matrix material.

Fiberglass has

the high strength of its glass fibers combined with the high ductility

of its polymeric matrix. This is because the two materials were

combined in the right way. Imagine if they were combined in such a way

as to obtain a composite material that was both weak and brittle! The

geometry of how composites are combined is just as important as their

constituent materials and the relative amounts.

The Matrix Phase

Although there are exceptions, in general the

purpose of the matrix phase is to transfer the load to the

fibers, prevent propagation of brittle cracks, separate the fibers

and protect them from surface damage. Usually Ef >>Em and the matrix is reasonably ductile.

There are 3 catagories of composites based on the matrix material:

- PMC - Polymeric Matrix Composites

These are relatively cheap and easy to fabricate. Their service temperatures are <200oC.

Examples include: - polyesters (cheap)

- vinyl esters (cheap)

- expoxies (more expensive but better properties and more resistant to moisture)

- polyimid resins (for relatively high temps)

- thermoplastic resins (for high temps)

- MMC - Metal Matrix Composites

These were developed to get high strength-to-weight ratios, better

performance at high temperatures and better conductivities. Although they are more expensive than PMCs, they have the advantages of being non-flammable, greater

resistance to degradation by organic fluids, good ductility and good load bearing capabilities.

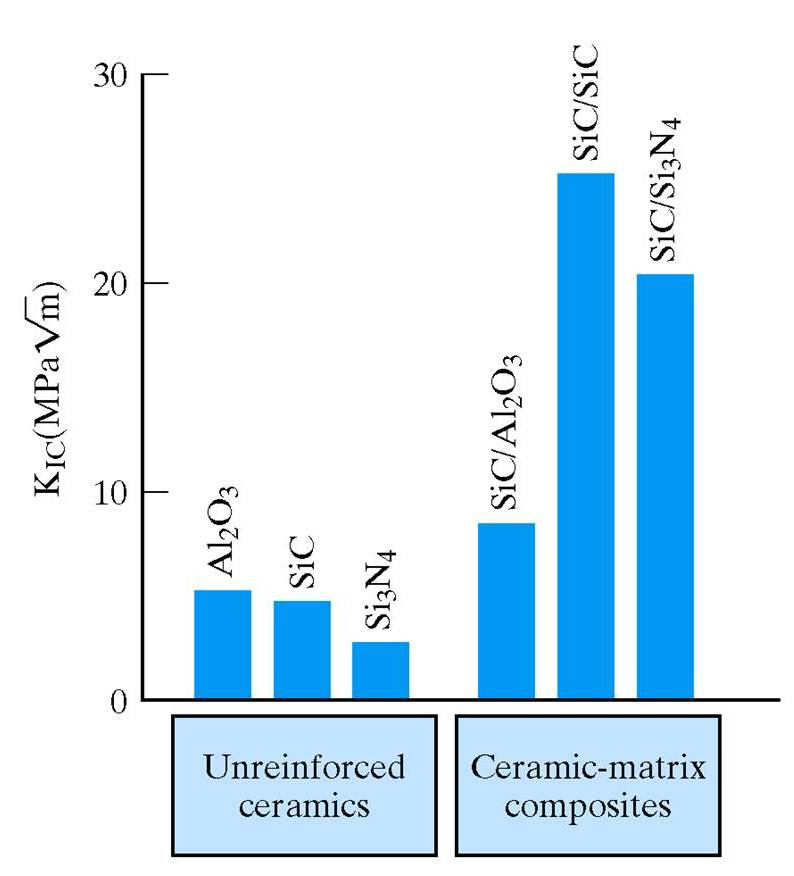

- CMC - Ceramic Matrix Composites)

These were developed

to get improved strength and toughness for high temperature applications. CMCs differ significantly from the others

in that the purpose of the reinforcing fibers is to increase ductility,

not strength. The

mechanism by which these materials are toughened is that the

reinforcing fibers interfere with crack propagation in the brittle ceramic matrix. This can

happen by crack deflection, crack bridging, or fiber pullout.

The Dispersed Phase

The

dispersed phase has a geometry that is either:

- aggregate particulates

These are more or less equi-axed

particles dispersed throughout the matrix phase.

- fibers

These are long, axial particles dispersed throughout the matrix phase in aligned or random arrangements.

Although

we won't consider these here, some

composites have other more complicated arrangements of

fibers that take advantage of sophisticated

geometries to gain desirable properties. Examples of these more

complicated composites are woven fabric layers

interspersed with a matrix phase or honeycomb stuctures.

Composite Properties

The properties of the resulting composite material will be dependant on:- the properties of the constituents

- the relative amount of each constituent

- the geometry (i.e. shape, size, orientation and distribution of dispersed phase)

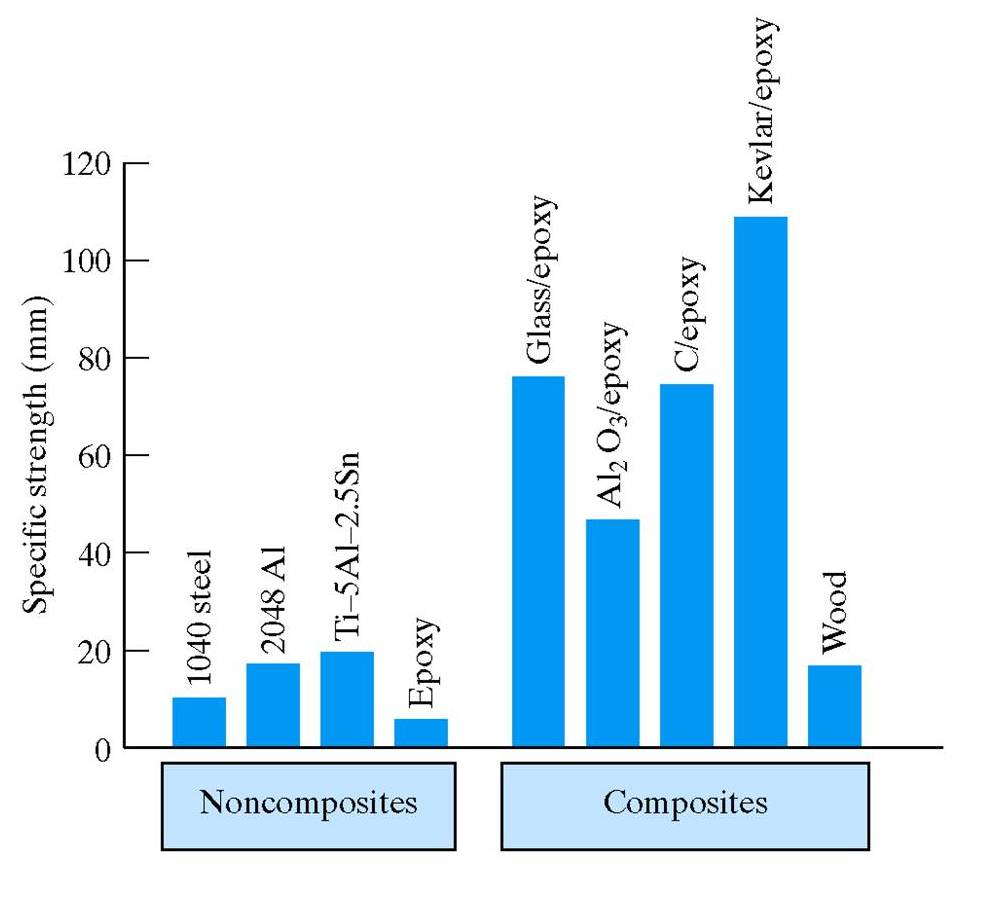

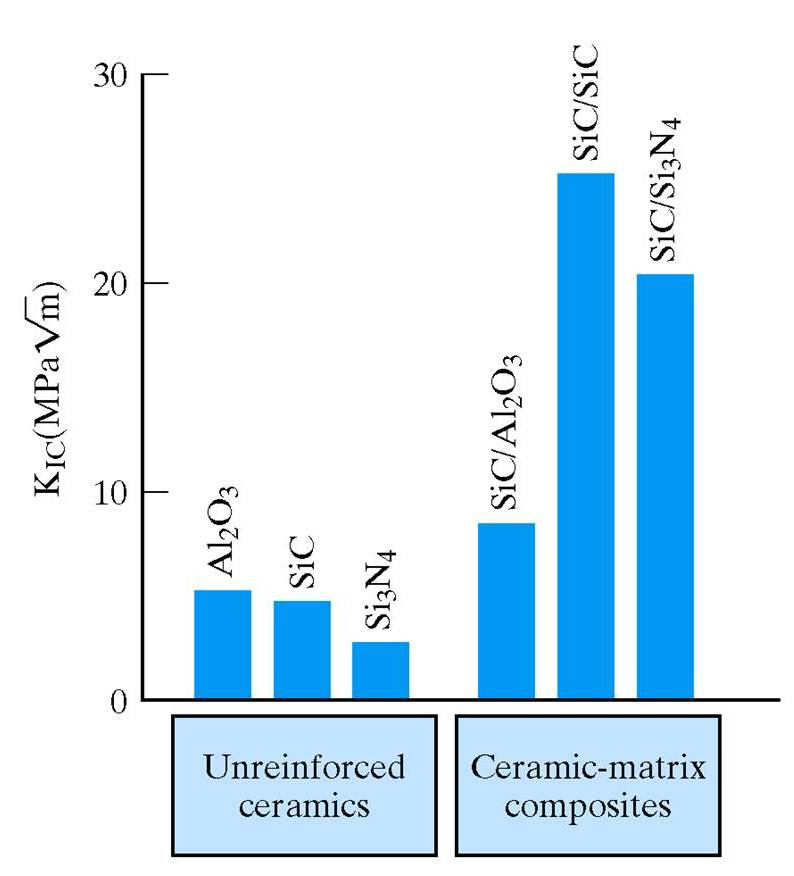

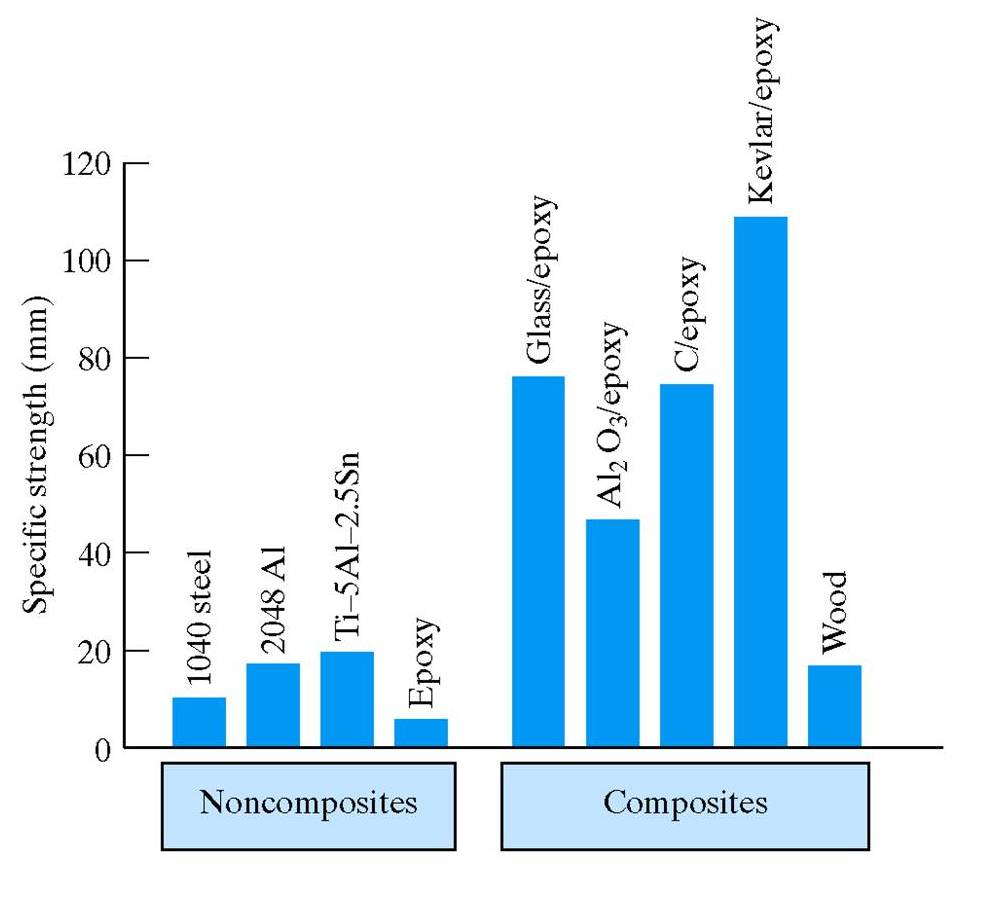

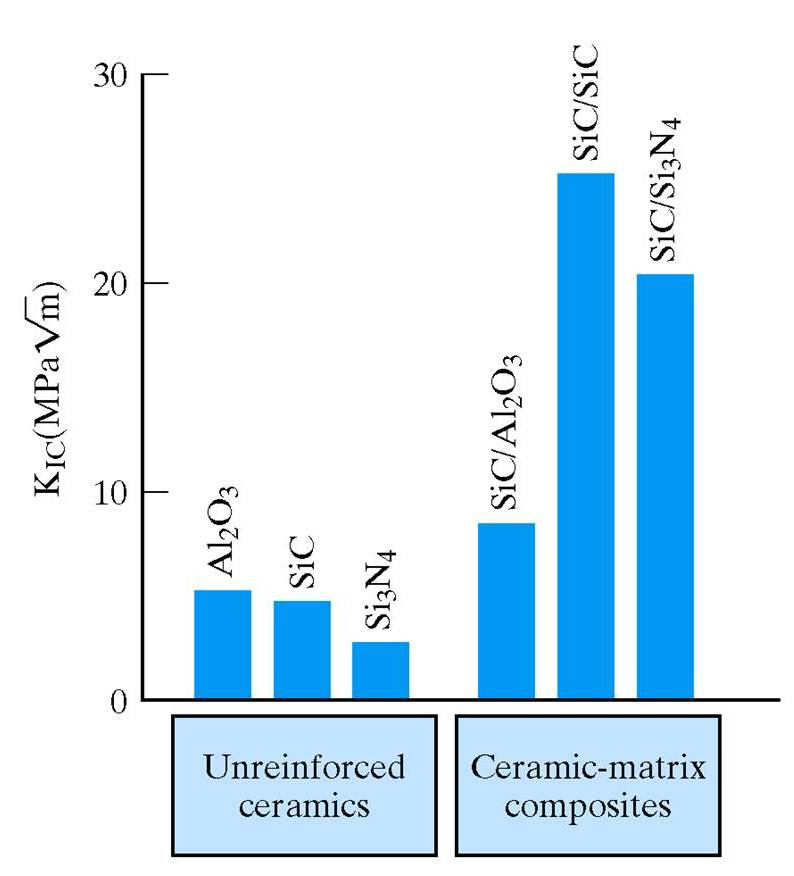

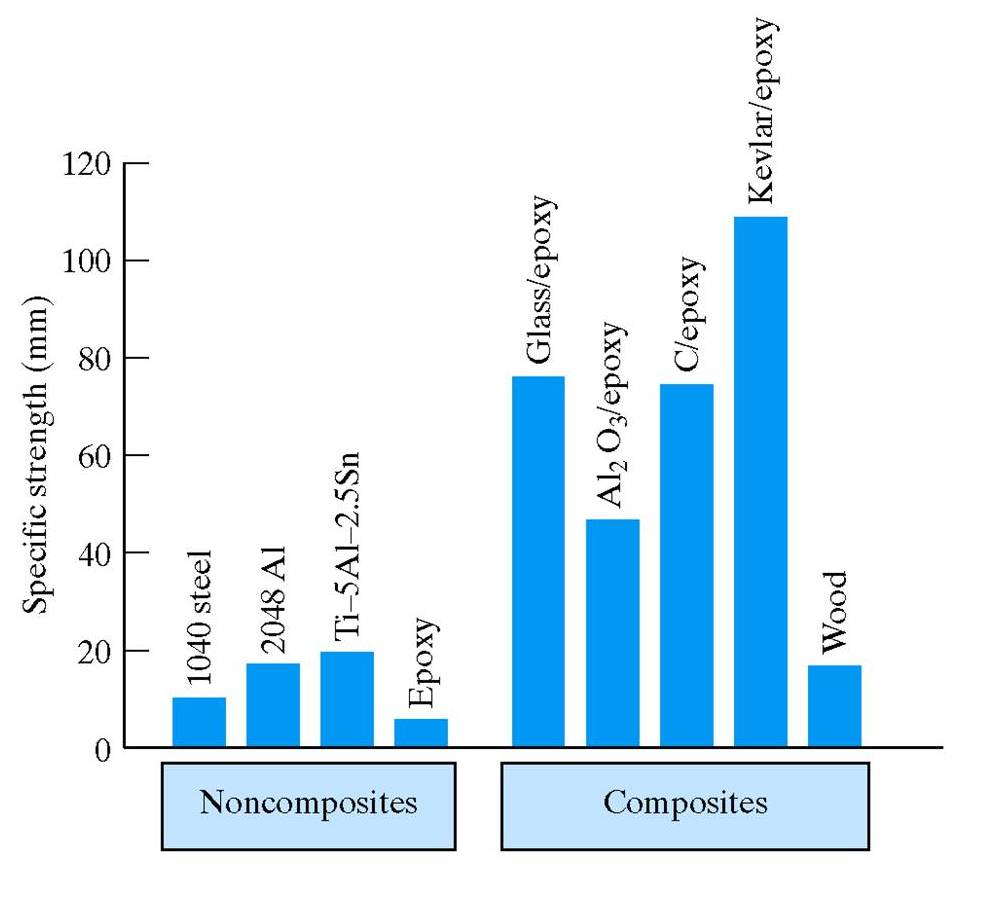

Superior Properties of Composites Compared to Non-composites

Consider

these two plots.

The first shows that the specific strength of epoxy is

substantially increased by adding a dispersed phase.

The second shows a substantial increase in fracture toughness of ceramics by the addition of a reinforcing phase.