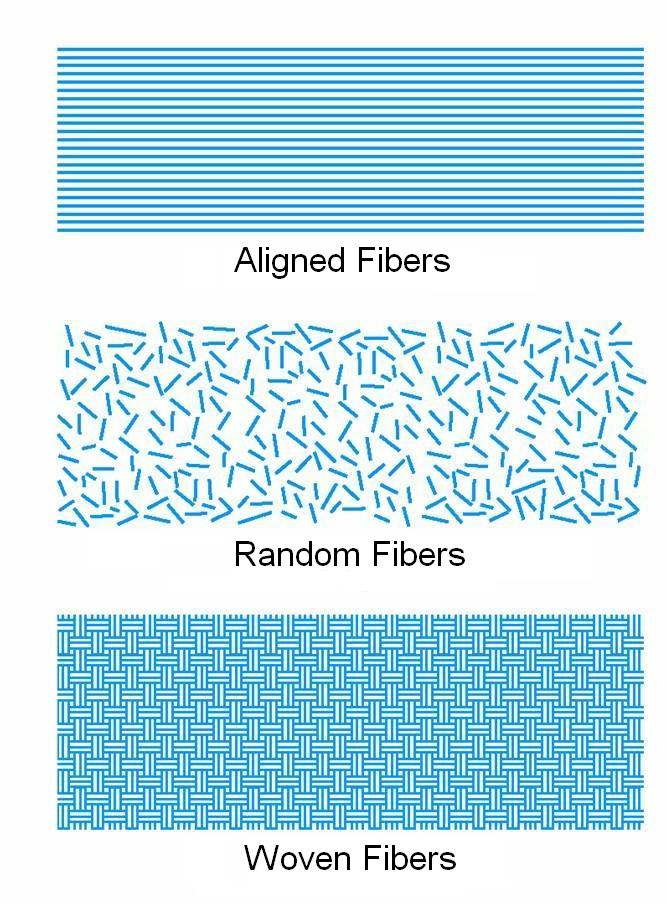

The properties of aligned fiber-reinforced composite materials are highly anisotropic. The longitudinal tensile strength will be high whereas the transverse tensile strength can be much less than even the matrix tensile strength. It will depend on the properties of the fibers and the matrix, the interfacial bond between them, and the presence of voids.

There are 2 different geometries for aligned fibers:

- Continuous & Aligned

The fibers are longer than a critical length which is the minimum length necessary such that the entire load is transmitted from the matrix to the fibers. If they are shorter than this critical length, only some of the load is transmitted. Fiber lengths greater that 15 times the critical length are considered optimal. Aligned and continuous fibers give the most effective strengthening for fiber composites.

- Discontinuous & Aligned

The fibers are shorter than the critical length. Hence discontinuous fibers are less effective in strengthening the material, however, their composite modulus and tensile strengths can approach 50-90% of their continuous and aligned counterparts. And they are cheaper, faster and easier to fabricate into complicated shapes.

This is also called discrete, (or chopped) fibers. The strength will not be as high as with aligned fibers, however, the advantage is that the material will be istropic and cheaper.

The fibers are woven into a fabric which is layered with the matrix material to make a laminated structure.